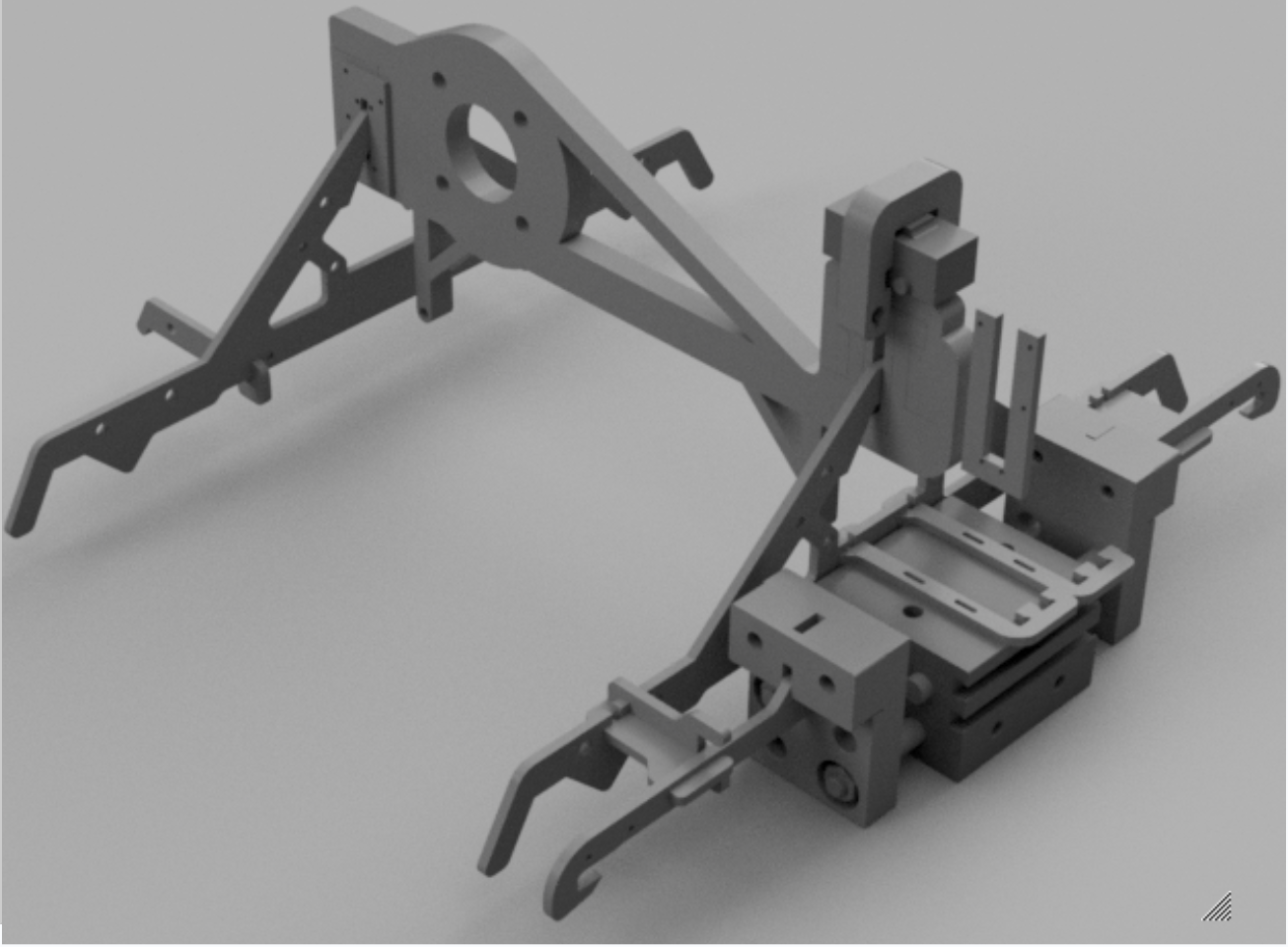

Basket Gripper End Effector

In 2021 I was employed as a mechanical engineer by a robotics startup called Nextera. Nextera was based in the Massrobotics startup incubator location in the Seaport district of Boston and while there I worked on a variety of projects. Many of these projects involved design and fabrication of end-effectors for 6-axis machine robot arms. One of the longest projects I did when working was developing an end-effector for use in Dunkin Donuts’ factories that could pick up metal baskets. I was given a already complete first version and was taked with optimizing it for extended use.

CAD Editing and Rendering

Rendering of Final Basket Gripper Prototype

Rendering of Basket Gripper in Use

The first task I was given was to modify the gripping parts to minimize friction of certain actuated metal parts rubbing against each other. In the rendering to the left the pieces that look like clothes hangers are connected via an upper frame which attaches to the robot arm. These pieces are required to be loose and move freely up an down while still being secured to the frame. An issue that was being encountered was that these parts were scraping the frame when moving up and down causing metal shavings to come off, degrading the frame. In order to rectify this,I designed and fabricated inserts made of delrin to go into these contact points and reduce the coefficient of friction.

Fabrication and Testing

After completing the CAD files for the new version I then had to fabricate them. Because all of the parts were complex and metal but mostly flat, I opted to use a water-jet cutting machine. The version you see in the images below is made from stainless steel and aluminium sheets of varying thicknesses. Also included in the assembly is a block for pneumatic tubing and cylinders to the hooks at the front can actuate and grab the basket. Over the course of this project I learned a lot about optimizing parts for specific use periods and how to machine metal parts from sheets.