Amazon Gatherers Project

In my 4th year semester during the spring of 2023, I was in a class at D-Lab called D-Lab Design. D-Lab is a lab at MIT which works with people around the world to develop and advance collaborative approaches and practical solutions for global poverty. In this class, I was part of a small team working on designing a device to climb açaí palms and harvest their berries. Our group collaborated with an international partner called Corpocampo, an organisation based in Colombia promoting sustainable development by supporting açaí harvesters in the Amazon. Over the course of the semester in collaboration with our partner we developed a proof of concept prototype to ascend end descend the palms. On this page I will take you through the development of this prototype via slides from our group’s final presentation.

Presentation

Our Project started similar to the other D-Lab project; with extensive interviews with people from CorpoCampo to get an understanding of the way current harvesting happening and the benefits and drawbacks. We got to talk to some harvesters and some farms who are supported by CorpoCampo and quickly realized that there is a large risk of injury and even death for the climbers. These palms can grow up to 80 and the berries are harvested near the top so it takes a lot of skill and training. The climbers do not usually have climbing equipment like ropes and harness because the palms sway and are likely to bend and even break high up. This is also why most climbers do not way more than 176 points (80 kg) so that the risk is diminshed.

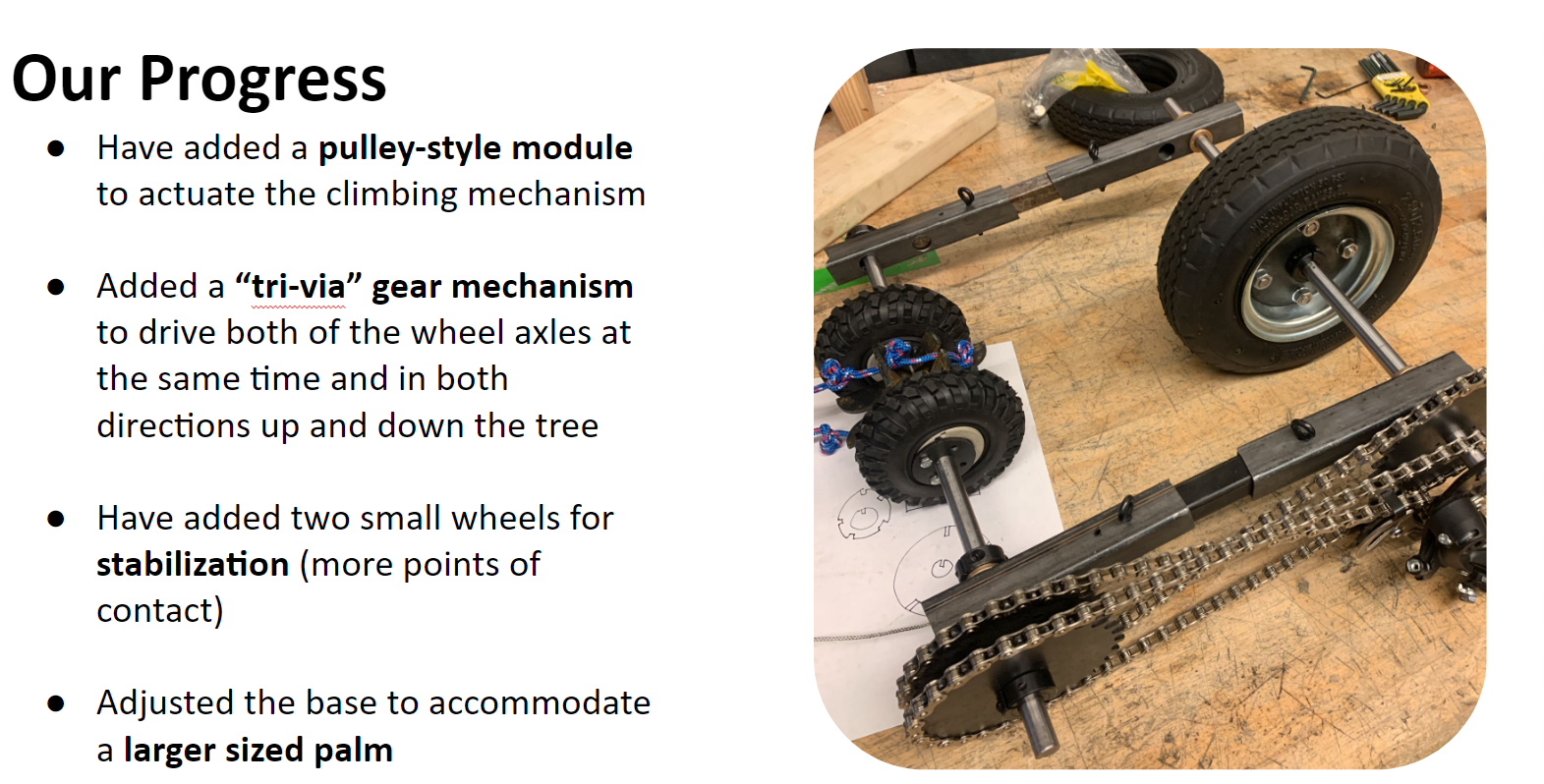

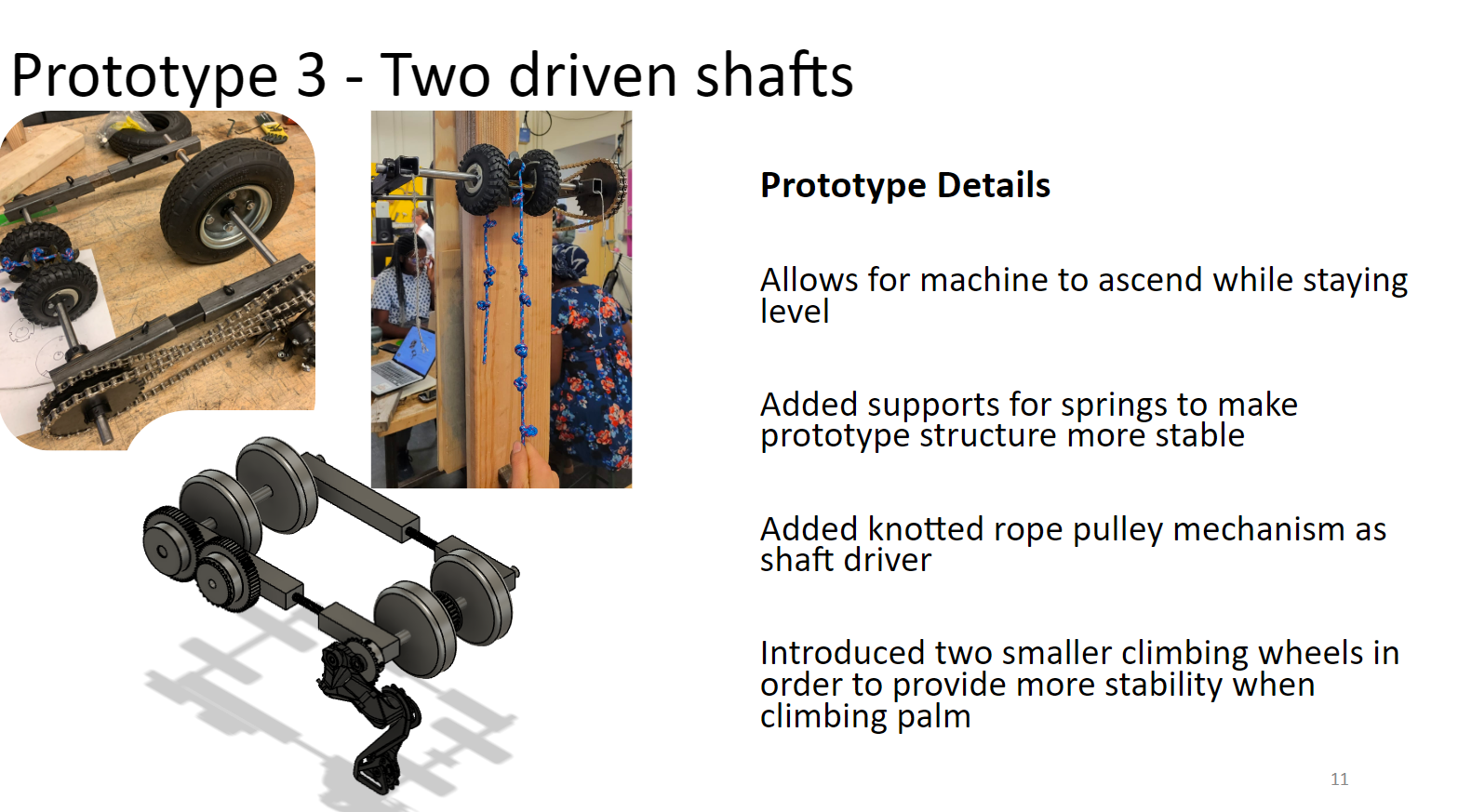

Building of off some mechanisms we made previously, The prototype uses wheels on opposite ends of the palm and is affixed to it via springs the in the main side bars which provide clamping force. The theory is that the wheels if driven by some ground mechanism can go up and down the tree. In our intial prototype we were only driving one wheel and the device was having difficulty climbing. We decided it would be better to find a way to drive both wheels and so after trying out a few different mechanisms we ended up using a bike chain and sprockets as they are easy to arrange and also are cheap and very plentiful in all parts of the world.

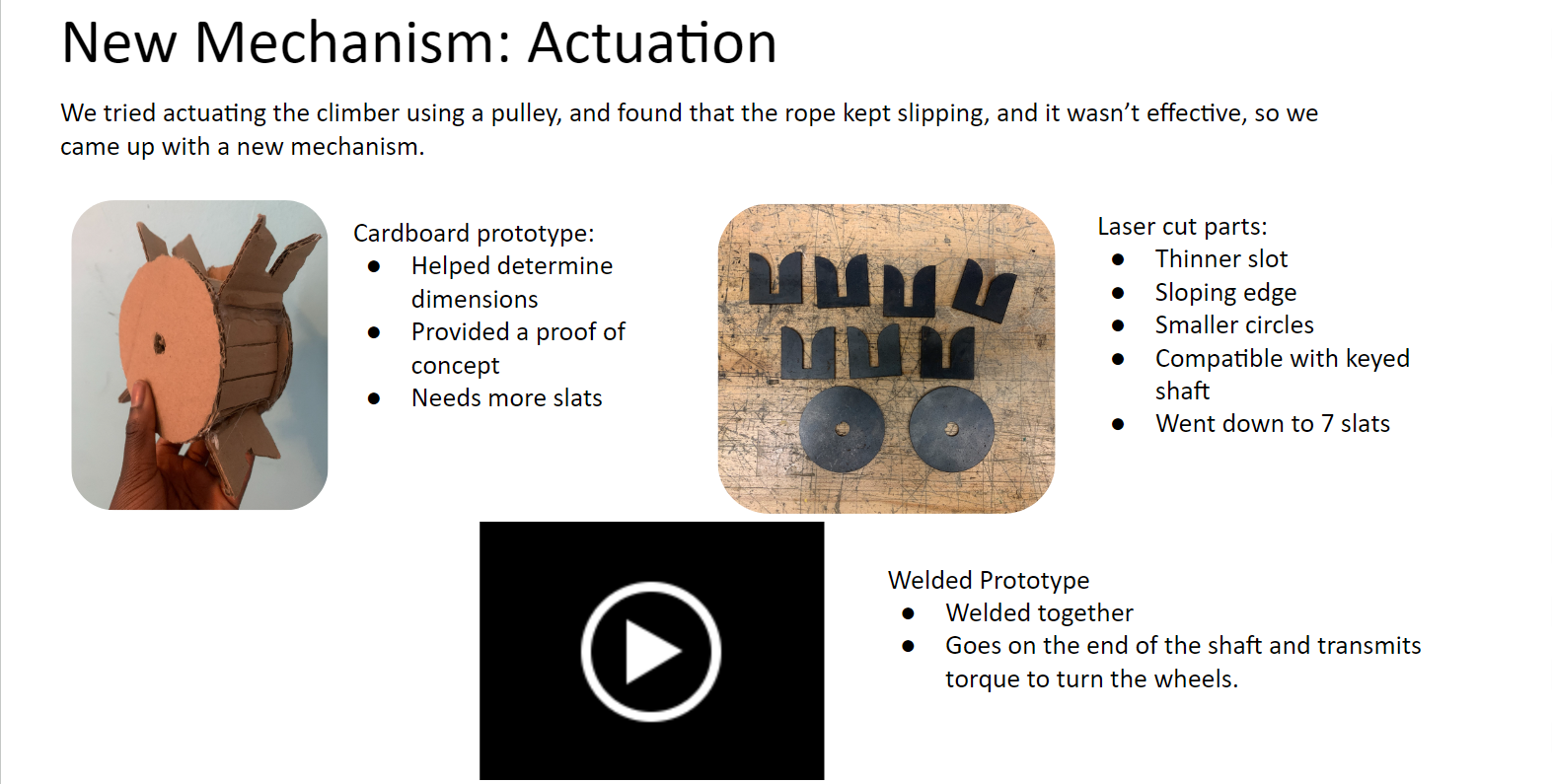

The mechanism to drive this machine is a wheel with slots attached to the axle between the two smaller climbing wheels. A knotted rope is fed throught these slots which turns the axle and the wheels causing it to climbs We first made a prototype out of cardboard for testing and after refining it we lasercut it out of metal and welded it together.

The way the wheel opposite to the driven one is actuated is via the bike chain and sprockets. Our group drew inspiration from a bike we saw online called the Tri Via gearing system. This chain arrangement on a bicycle allows for it to be driven forward no mater which way the cyclist is pedaling (forward or backward). We implement a similar type of chain arrangement so that no mater which way our device is driven, the wheel opposite of the roped one will always spin in the opposite direction.

Slide above shows CAD model of the climbing device as well as provide some general information.

This slide contains some of the current problems we were working out and some next steps we wanted to do when the semester ended.